Silent gear

Sinotruk T7H series damper actuators

Electric water valve series

stepping motor

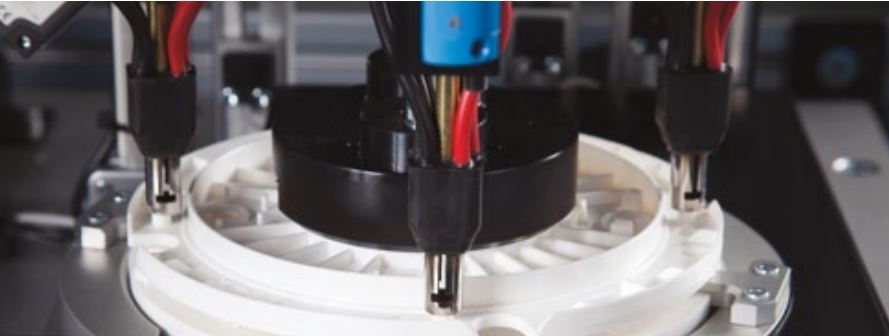

Seitz China focus on gear actuator, gear box, gear pump and drive system product assembly. We have many reprocessing capacity for plastic product, like ultrasonic welding, spin welding, hot riveting, UV glue solidifying, waterproof coating, lathing drilling, etc. In the aspect of assembly, we have long trained and stable workforce, 19 years assembly experience, 14 production lines and factory annual production capacity achieve 1 million kits. Seitz integrates FMEA, MSA, CONTROL plan, WI, SPC, 8D and other quality management tools into the visual production information platform, linking with engineering quality in real time to monitor the whole process quality, and realizes production automation through image recognition automatic tooling to improve production efficiency and consistency of production quality.

To ensure product reliability and consistency, the assembly line is equipped with foreign equipment, which has precise control and confirmation of each process. Professional personnel provide professional training and guidance to employees, and achieve comprehensive quality control for each process. The production output is monitored in real time to validate the appropriate and best takt time. The professional production line includes the assembly and testing line for medical device, food and beverage products, automotive parts, etc.

Assembly has also benefited from our continuous investment in Poka-Yoke devices and assembly aids to balance flow and make it more difficult every day to produce nonconforming parts.

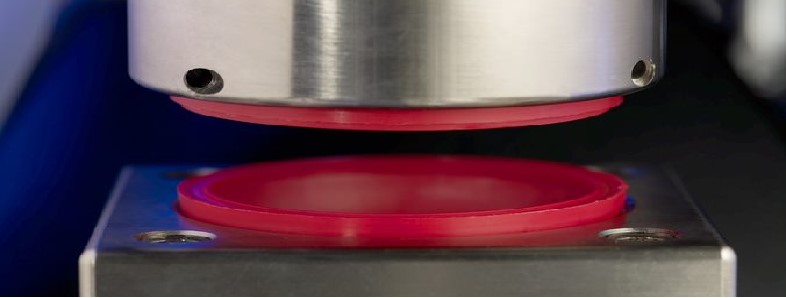

Through the use of ultrasonic waves, a precise location on both pieces of plastic can be bonded to the exact specifications required by our customers. This is a very fast, efficient and reliable method of joining plastic parts and components with a durable, lasting bond. There is also no need to finish the joint area as the pressure is applied to allow for a smooth, flawless surface to the joint.

Spin welding joins thermoplastic parts with a circular joint area by bringing the part interfaces together, under pressure, with a circular motion. Advantages for spin welding include strong, hermetic seals and its feasibility with most thermoplastic materials.

Heat staking also known as thermoplastic staking is the process of joining two dissimilar materials together. In heat staking we use local heating and cooling to raise the temperature of plastic components and allow plastic reforming to be carried out. This reforming can be used in a wide variety of applications.

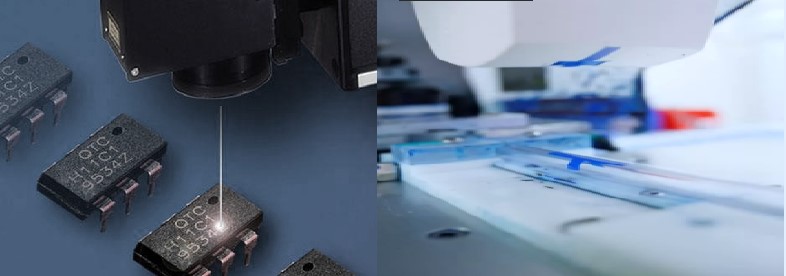

The automatic screw arranging machine is mainly developed to simplify the operation process of workers and reduce the labor intensity of workers in the traditional screw locking process. The main function is to arrange the screws neatly and send them to the designated position, and the electric batch operator can directly take the material, simplify the traditional locking action, and improve the production efficiency.

Whether your printing needs are for indicator marks, numerical characters, company logo’s or other markings, we work with a wide range of substrates and inks to find a solution offer Laser print, and Hot Stamping services for your need.