Silent gear

Sinotruk T7H series damper actuators

Electric water valve series

stepping motor

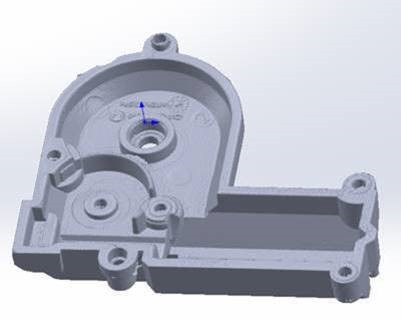

Plastic gear mold is different from the traditional plastic mold design, gear tooth thickness of the module of pressure Angle spiral Angle needs to be combined with the empirical data modification, and cannot be processed directly based on the shrinkage rate, Seitz in China, on the basis of platform to calculate the palstic gear mold cavity parameters, generate cavity profile, and applies in gear modification to improve the precision of gear profile.

Our company has rich experience in optimization of displacement coefficient, distribution of meshing Angle, optimization of calculation of slip rate and check of coincidence degree, etc. The designed high-precision gear profile includes spur gear, helical gear, compound gear, worm gear and ring gear, etc., which can be directly used in wire cutting and discharge machining, improving the machining accuracy and efficiency of mold. At present, the precision of mass production straight gear can reach AGMA level 10.

Thickness analysis filling analysis fuse analysis warping analysis gear deformation analysis.

Simulate the process of mold injection, predict the product deformation, shrinkage, lack of glue, trapped gas and other defects, to avoid the possible problems in mass production in advance.

According to the injection molding process design and material scheme, using mold flow analysis to optimize the molding process parameters, to provide the overall solution.

Design scheme comparison, improve the efficiency of mold testing, reduce the cost of mold testing, shorten the development cycle.

Precision laser metal 3D printing accompanied by cooling waterways

Cooling waterway is designed according to product structure

Grasp of product thickness

Prediction of mold temperature and resin temperature

Prediction of die strength surface

Prediction of necessary diameter of waterway prediction of necessary flow length

Prediction of velocity streamline orientation of fluid

Roughness residual stress of waterway inner wall

Can realize the automation of the involute planetary gear tooth shape parameter design drawing and 3 d modeling, etc For technical problems, such as the efficiency of the gearbox noise and life, seitz U.S. precision gear technology platform will be effective on planetary gear tooth interference check, meshing Angle of optimizing the allocation of modification coefficient, optimizing the calculation slip rate and coincidence degree and checking calculation.

Full range of gear modeling

Parallel shaft gear calculation

Gear Stress Validation

Transmission efficiency calculation

Transmission quality analysis

It is an advanced method that can build virtual 3D models based on existing physical components through CAD, CAM and CAE software. Through this means, it can analyze the operation mode of products, component composition, estimate budget and identify potential infringement behaviors.

Shorten the product design and development and mold manufacturing cycle, speed up the replacement of products

Reduce the cost and risk of developing new products

Accelerate product modeling design

Suitable for single small batch parts manufacturing, especially mold manufacturing